“There is no future without a past” – Haibike Visit

“Zukunft braucht Herkunft” (“There is no future without a past”): This slogan stands proudly in big letters on one of the huge white walls in the sacred halls of the Schweinfurt bike manufacturer Haibike.

Looking at the latest creation of the Lower Franconians, the Haibike XDURO NDURO Pro 26, it is hard to see how this down-to-earth and traditional motto could relate to this particular company. Why not? Because the NDURO is simply extraordinary, extravagant, and extreme! The boundaries of a standard production e-mountainbike have never been pushed as far as they have been with this bike. Its brutal appearance, massive 180mm of travel, and the outstanding and extremely expensive spec are evidence of this.

When you take a look at the company’s history, however, you soon understand what their slogan is based on. The company Haibike was founded in 1996 by Susanne and Felix Puello, but it was Susanne’s grandfather, Engelbert Wiener, who in 1914 laid the foundations for the company’s success in the production of bicycles with the company E.Wiener Ltd. in Schweinfurt. Following a few mergers and

acquisitions, Haibike is now part of the Winora

Group alongside such companies as Winora and Staiger based in Schweinfurt.

But there is more than just history behind the company slogan. It is also reflected in the Haibike products. By looking at each part of it separately, you can see why.

Future: E-bikes are the future, of this there is no doubt. Haibike was one of the first bicycle companies to realize this, and as early as 2010 it introduced the first bike with a Bosch midship motor innovatively integrated into the front triangle of the frame.

The suitability of e-mountainbikes for off-road use was thus established; the weight is placed in the centre of the bike and not at the rear wheel as it was in other designs. The XDURO NDURO Pro 26 is simply the next logical and necessary step on the way to a new kind of cycling.

Past: Walking through the company headquarters in this industrial city, you soon realize what the word means. More than 250 employees work for the Winora group in Schweinfurt, from engineers to assemblers, in one of the two production lines. All are directly involved in the development and production of the bicycles “made in Germany.”

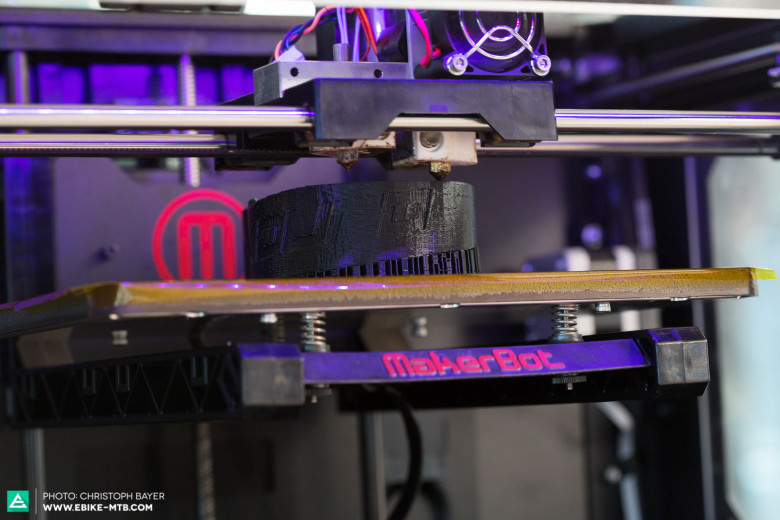

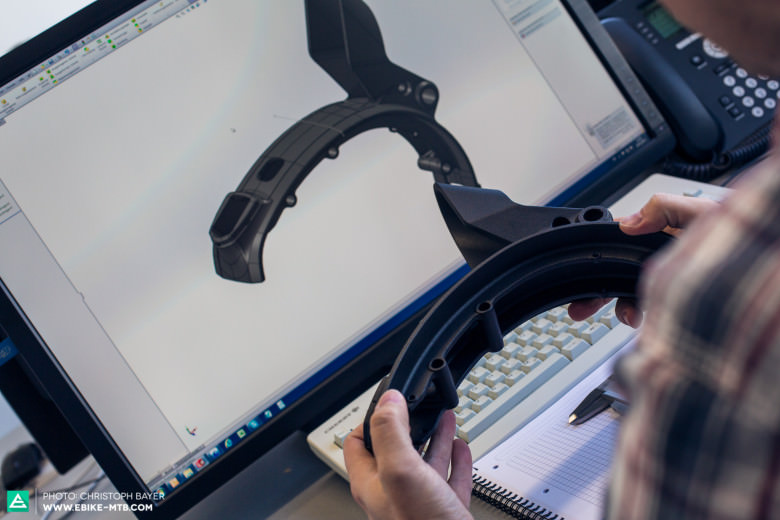

Many of them are cyclists themselves, from ambitious racers to bicycle commuters who ride to work every day. Nearly every type of rider is represented. The development of a frame always starts with a large number of drawings on paper, the most promising of which are subsequently modeled in 3D on the computer with the help of engineers and product design workers. The whole process up to the submission of the final design takes place in-house. A 3D printer makes it possible to create various functional models to check the freedom of movement and compatibility of all components locally.

After the frames have been constructed on the other side of the world, they come back to Schweinfurt for the final assembly. Due to the current e-bike boom, the factory is running at close to full capacity. At various production line stations the motor is placed in the frame, components are attached, and the bikes undergo a final inspection before being transferred to the huge external warehouse with space for 50,000 bikes. There they wait to be delivered to the four corners of the globe; the production circle is completed, and the slogan in the reception hall proves its validity. The employees can identify closely with all the bikes they are helping to create and thus… There Is No Future Without A Past!

Text & Photo: Christoph Bayer

Did you enjoy this article? If so, we would be stoked if you decide to support us with a monthly contribution. By becoming a supporter of E-MOUNTAINBIKE, you will help secure a sustainable future for high-quality cycling journalism. Click here to learn more.